Today, we interviewed our technician Tim, and Keditec has organized the text.

Question: We know that a printer has many boards. How can we classify them by functional type?

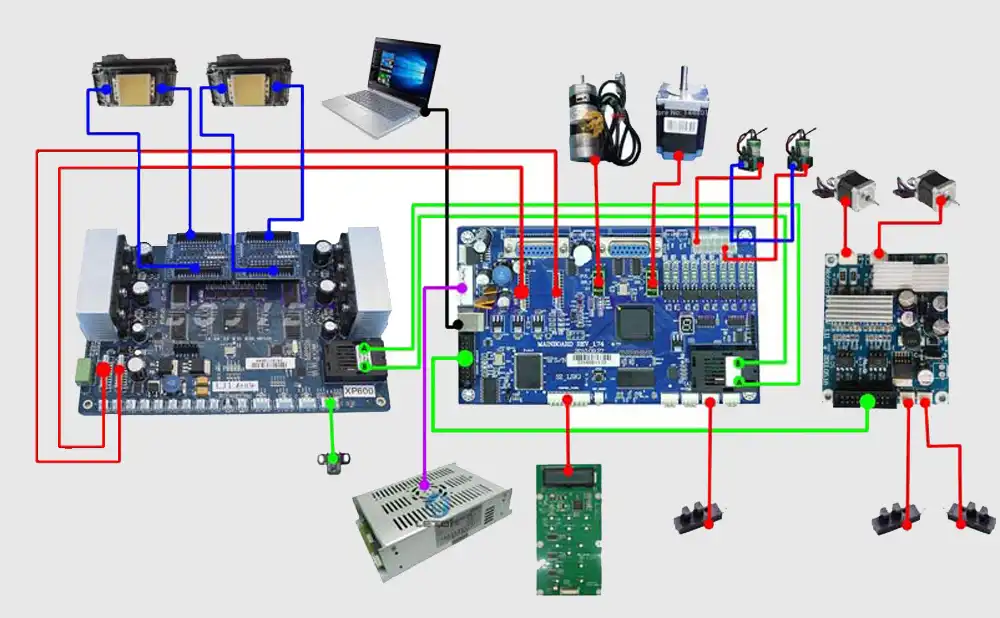

Answer: There are currently four major modules, which may be integrated into one in the future as the industry develops.

Answer: There are currently four major modules, which may be integrated into one in the future as the industry develops.

- Main Control Board

- It is the core control component of the printer, equivalent to the motherboard of a computer. It coordinates the work of various printer components, including controlling the movement of the print head, inkjetting, the operation of the transmission system, and communication with computers or other external devices.

- The performance of main control boards varies among different models of DTF printers. High-end models typically have stronger processing capabilities and more stable performance, supporting higher print resolution, faster printing speed, and more complex printing tasks.

- Print Head Driver Board

- Mainly responsible for driving the print head, precisely controlling the ink ejection volume and timing of each nozzle in the print head.

- The performance of the print head driver board directly affects print quality, such as whether precise ink drop control can be achieved to ensure image details and color accuracy. Some high-quality print head driver boards also have print head fault detection and automatic compensation functions. When a nozzle fails, they can automatically adjust ink drop distribution to minimize the impact on print results.

- Transmission Control Board

- Used to control the printer’s transmission system, including motors, belts, gears, and other components, ensuring that the print platform and print head can move accurately along the preset path.

- The accuracy of the transmission control board is crucial for printing accuracy, ensuring the positional accuracy and repeatability of the printed pattern to avoid issues such as pattern misalignment or deformation. Some advanced transmission control boards also support multiple movement modes and speed adjustments to adapt to different printing materials and requirements.

- Interface Board

- Provides connections between the printer and external devices (such as computers, scanners, memory cards, etc.), with common interface types including USB, Ethernet, HDMI, etc.

- The role of the interface board is to enable fast data transmission and stable communication, ensuring that the printer can timely receive print commands and image data from external devices. It may also have data processing and caching functions to optimize data transmission and processing efficiency during printing.

Technician Tim’s Suggestions:

When selecting DTF printer boards, consider factors such as compatibility, stability, performance, and scalability. High-quality boards can improve the overall performance and reliability of the printer, reduce the probability of failures, and provide support for future equipment upgrades and functional expansions. In addition, some printer brands may offer customized board solutions to meet the special needs of different users.

When selecting DTF printer boards, consider factors such as compatibility, stability, performance, and scalability. High-quality boards can improve the overall performance and reliability of the printer, reduce the probability of failures, and provide support for future equipment upgrades and functional expansions. In addition, some printer brands may offer customized board solutions to meet the special needs of different users.

Question: Which brands are recommended?

- Hanson: Hanson boards are often used for adapting Epson print heads and have a certain market share in print head adaptation for inkjet printers, digital textile printing, and UV printers. The products have advantages in signal transmission stability and print head control accuracy.

- Weiliyin: Can customize and develop a full series of board products according to user needs, including main boards, carriage boards, driver boards, button boards, and cover boards, providing customized development services for printing equipment manufacturers and printing enterprises to comprehensively control print quality.

- Hongmei: Boards have good compatibility and can adapt to multiple models of print heads and printers.

- And others.

Question: What types of boards are generally used in Keditec’s DTF printers?

Answer: Boards can be ordered according to customer needs, with Hanson boards used by default.

Answer: Boards can be ordered according to customer needs, with Hanson boards used by default.

Question: What are the common faults of DTF printer boards?

Answer: There are many types of main control board faults, which I have summarized into four categories:

Answer: There are many types of main control board faults, which I have summarized into four categories:

- Main Control Board

- Faulty power chips or capacitors, making the printer difficult to start.

- Faulty crystal oscillators, causing instability or frequent crashes after startup.

- Faulty interface chips, leading to failed device connections.

- Faulty communication chips, resulting in poor data transmission.

- Print Head Driver Board

- Faulty driver chips or power circuits, causing the print head to stop inkjetting.

- Signal line issues, leading to streaks or missing dots in printed patterns.

- Control program errors, causing incorrect print colors.

- Transmission Control Board

- Faulty motor driver chips, causing print head jams or unstable speeds.

- Faulty position sensors, leading to inaccurate print head positioning.

- Communication failures with the main control board, causing pattern misalignment or deformation.

- Interface Board

- Dirty or loose interfaces, leading to unstable device connections.

- Faulty filter circuits, causing data transmission interference.

- Faulty data conversion chips, leading to incorrect reception of print commands.

Question: How to maintain and service DTF printer boards to reduce faults?

Answer: Focus on four aspects: keep clean, maintain suitable temperature, follow power-on procedures, and conduct regular inspections.

Answer: Focus on four aspects: keep clean, maintain suitable temperature, follow power-on procedures, and conduct regular inspections.

- Keep Clean: Dust can poor heat dissipation and even cause short circuits. Use compressed air cans or soft brushes to clean areas prone to dust accumulation, such as fans, heat sinks, and interfaces. Avoid placing liquids near the printer; if liquid spills accidentally, power off immediately, absorb the liquid with paper towels, and let it air-dry or use a low-temperature hair dryer.

- Stable Environment: The ideal temperature is 15°C–30°C, and humidity is 40%–60%. Use air conditioners or dehumidifiers to adjust if necessary. Keep away from large motors, transformers, and other sources of electromagnetic interference. Use shielded data cables and ensure proper grounding.

- Standard Operation: Power on the printer first, then the computer; reverse the order when shutting down. Avoid frequent switching, as it can damage boards. Never plug or unplug boards or cables while the printer is running. Wait for capacitors to discharge after shutting down before operating.

- Regular Inspections: Check for loose or oxidized board interfaces and damaged cables, repairing or replacing them promptly. Monitor manufacturer-released driver and firmware updates and install them in a timely manner. Use tools like multimeters to regularly test power circuits and signal lines to identify and resolve potential issues in advance.

Summary:

Technician Tim from Keditec introduced that the electronic boards of DTF printers are functionally divided into four modules: main control, print head driver, transmission control, and interface boards. The main control board is the core, coordinating all components; the print head driver board controls inkjetting and affects print quality; the transmission control board ensures precise movement paths; and the interface board enables data transmission with external devices. When selecting boards, consider factors like compatibility and stability, with recommended brands including Hanson, Weiliyin, and Hongmei. Keditec uses Hanson boards by default. Common board faults include startup and communication issues in main control boards, unresponsive print heads and poor print quality in driver boards, abnormal movement in transmission control boards, and unstable connections in interface boards. Daily maintenance should focus on keeping boards clean, maintaining suitable environmental conditions, following standard operation procedures, and conducting regular inspections to reduce faults.

Technician Tim from Keditec introduced that the electronic boards of DTF printers are functionally divided into four modules: main control, print head driver, transmission control, and interface boards. The main control board is the core, coordinating all components; the print head driver board controls inkjetting and affects print quality; the transmission control board ensures precise movement paths; and the interface board enables data transmission with external devices. When selecting boards, consider factors like compatibility and stability, with recommended brands including Hanson, Weiliyin, and Hongmei. Keditec uses Hanson boards by default. Common board faults include startup and communication issues in main control boards, unresponsive print heads and poor print quality in driver boards, abnormal movement in transmission control boards, and unstable connections in interface boards. Daily maintenance should focus on keeping boards clean, maintaining suitable environmental conditions, following standard operation procedures, and conducting regular inspections to reduce faults.